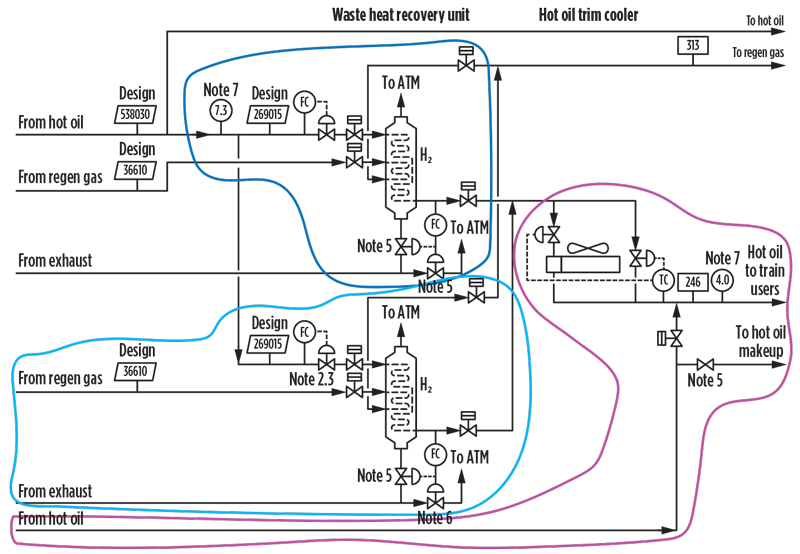

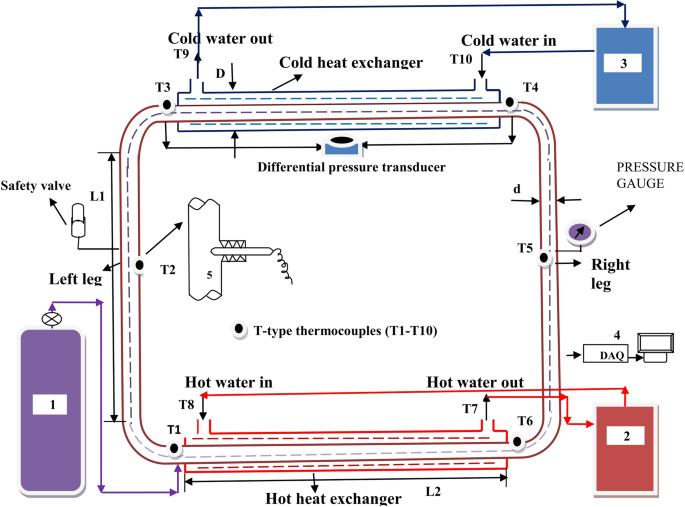

Hot Oil System Process Flow Diagram

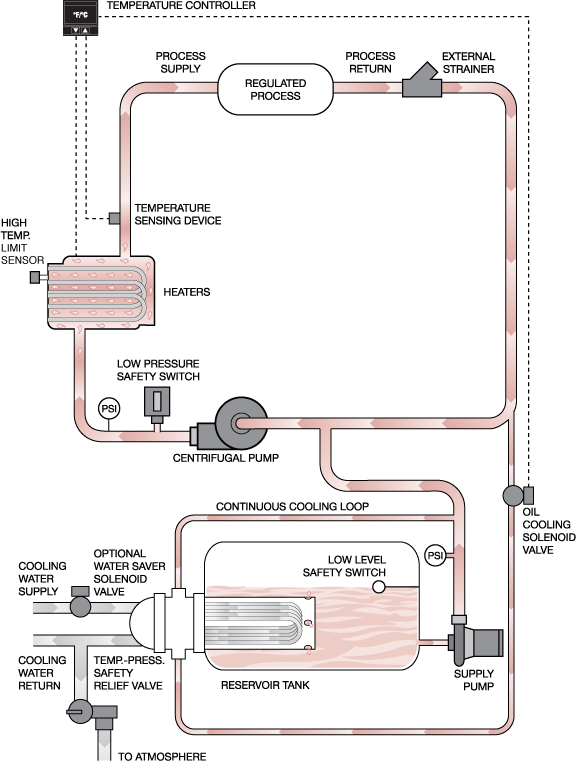

Hot oil system process flow diagram. Pre-drawn process heating symbols represent batch oven calendar circulation heater compensator condenser evaporator expansion loop heat exchanger etc. Axens H-Oil Process - Flexibility. An expansion tank vented to atmosphere and elevated above the system maintains a constant positive suction head on the pump.

Teheran - November 2017. Fig2 describes similar process flow diagram of hot oil system commonly employed in oil and gas plants. Solar Heating - Direct Pumped System.

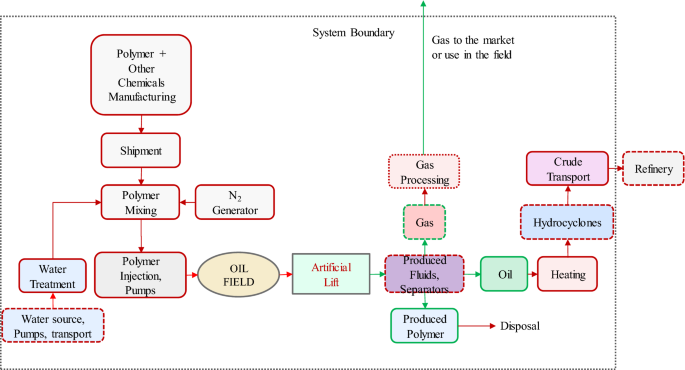

This is what is colloquially known as the first smoke pass. The catalyst is continuously regenerated. Widely used in process industries especially in oil and gas plants as a heating medium hot oil is.

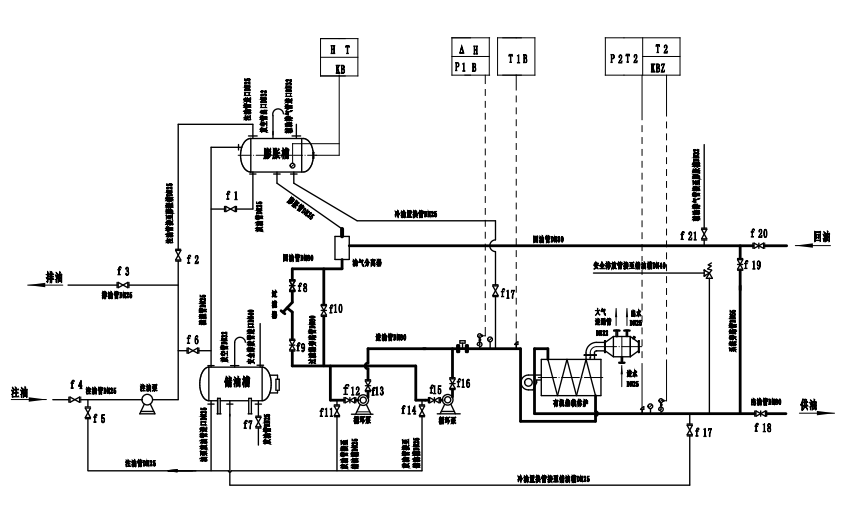

A10 Diesel Hydrodesulfurisation Unit DHDS The purpose of this unit is to hydrotreat a blend of gas oil diesel oil and kerosene or LCO in order to produce a low sulphur content gas oil. Não possui uma conta. Oil and Gas Processing Oil Section The typical process flow diagram PFD of oil and gas processing for most of fixed or floating offshore production.

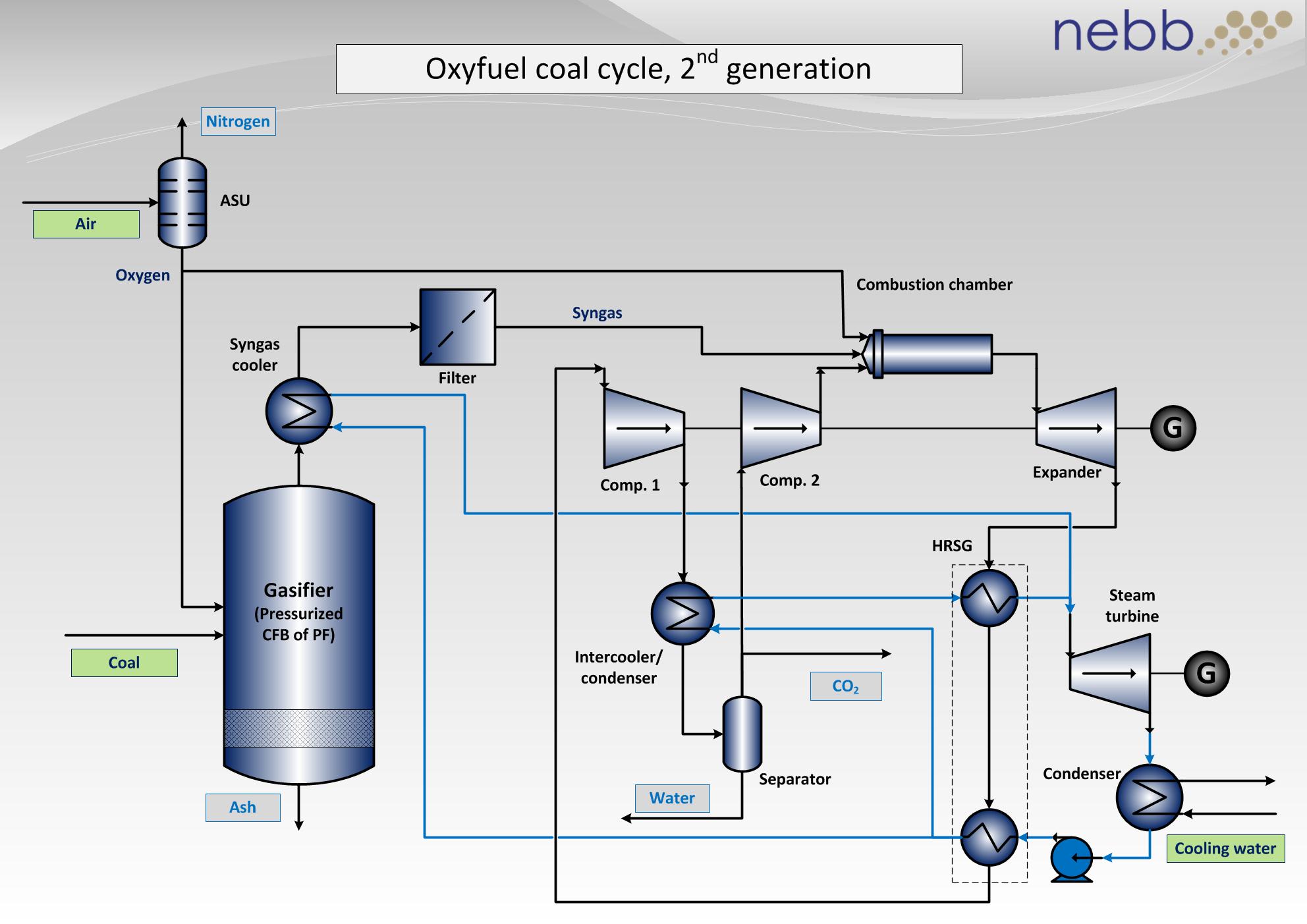

H-Oil Overall Block Flow Diagram Outstanding catalytic system H-Oil ACS. It must be designed in accordance with the appropriate codes. The level of detail can be decided by the team.

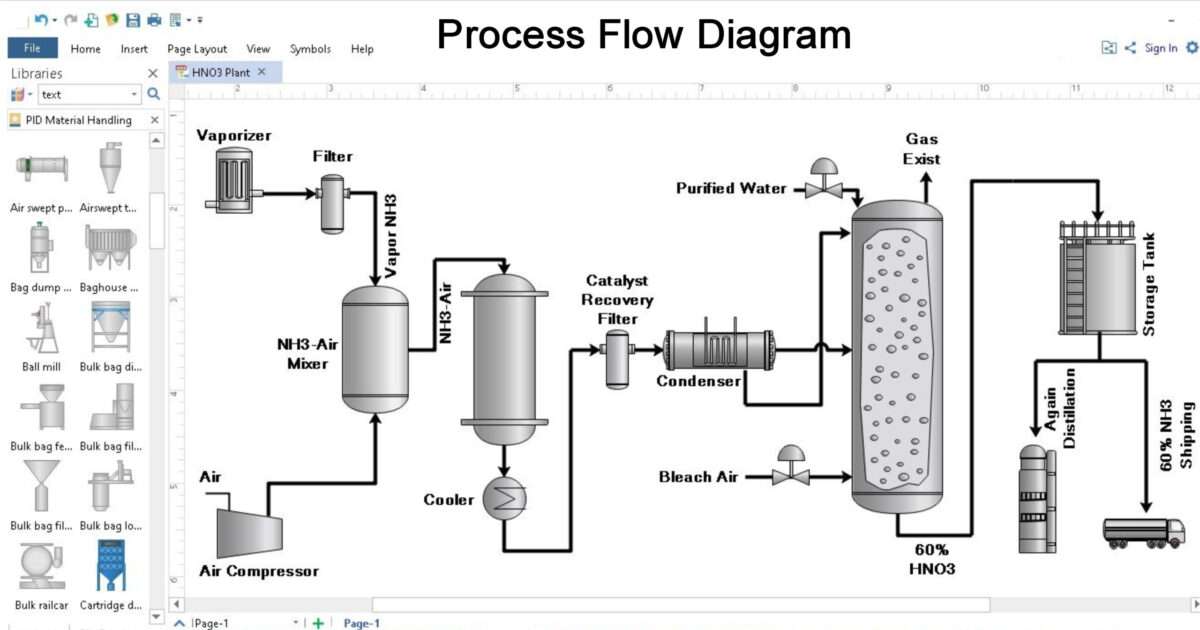

A PFD helps with the brainstorming and communication of the process design. Process Flow Diagrams PFDs are a graphical way of describing a process its constituent tasks and their sequence. PID Process Heating Symbols and Their Usage.

The Complete Process diagram is given in Fig. Heat should be applied in 20F 11C to 25F 14C increments until the heat transfer fluid gets to a viscosity of 10 cP centipoise or less.

A PFD helps with the brainstorming and communication of the process design.

76 Process Steam Generation by the Package Boiler Process-Base Case Process Flow Diagram D-3 77 Cogeneration of Steam and Electricity by the Combined Cycle Process Process Flow Diagram D-5 81 Pressure Swing Adsorption PSA Process for Nitrogen Separation 8-3 82 Membrane Process Flow Diagram for Nitrogen Sep aration 8-5. Ad Use Lucidchart to visualize ideas make charts diagrams more. Heat should be applied in 20F 11C to 25F 14C increments until the heat transfer fluid gets to a viscosity of 10 cP centipoise or less. A PFD helps with the brainstorming and communication of the process design. Flow Diagram The heat transfer fluid is circulated through the electric heaters and the process in a closed loop. Vector symbols help develop accurate and presentation-quality diagrams and documentations. Find out why pros choose Lucidcharts to make process diagrams. It must be designed in accordance with the appropriate codes. Create Process Flow Diagram examples like this template called Solar Heating - Direct Pumped System that you can easily edit.

First you start your system pump to get the fluid flowing through the system. Axens H-Oil Process - Flexibility. Widely used in process industries especially in oil and gas plants as a heating medium hot oil is. The transfer of process heat as a liquid offers these System 1 is the basic system configuration with a single benefits to the installation. Teheran - November 2017. Heat should be applied in 20F 11C to 25F 14C increments until the heat transfer fluid gets to a viscosity of 10 cP centipoise or less. Vegetable oil refinery plant hot soybean oil refining process palm oil processing hine flow chart of palm kernel oil refining small scale edible oil refinery line.

-crude-oil-distillation-unit---pfd.png--diagram-flowchart-example.png)

Posting Komentar untuk "Hot Oil System Process Flow Diagram"